MIL-DTL-23938B(AS)

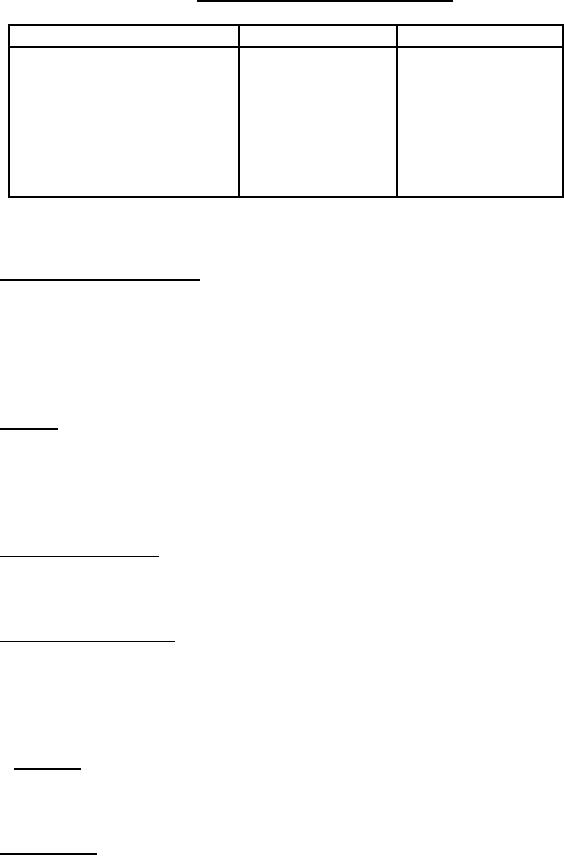

TABLE I. Chemical and physical requirements.

Characteristics

Minimum

Maximum

-

Iron as Fe2O3

98.70 %

0.20%

-

Volatiles

0.20%

-

HCl solubles

0.10%

-

SiO2

0.20%

-

H2O soluble

0.20%

-

Sieve analysis - Retained on

US standard sieve No. 325

4. VERIFICATION

4.1 Classification of inspections. The inspection requirements specified herein are classified

as follows:

a. First article inspection (see 4.3).

b. Conformance inspection (see 4.4).

4.2 Lot size. A lot shall consist of material produced by one manufacturer in one continuous

operation employing not more than one lot of each ingredient and with no change in formulation

or process. If manufacture is by batch process, batches may be combined to form a lot provided

that not more than one lot of each ingredient and no change in formulation or process is used (see

6.2).

4.3 First article inspection. First article inspection shall consist of all the conformance

inspections and requirements of this specification, when a first article inspection is required

(see 3.1).

4.4 Conformance inspection. Conformance inspection shall consist of all the test methods in

4.5 to determine compliance with section 3. Other test methods may be used if they offer

assurance of equal results. If test methods differ from those specified herein, a copy of those

methods or reference to available source for the methods shall be furnished to the acquiring

activity.

4.4.1 Sampling. Sampling for conformance inspections shall be as specified in the contract

or purchase order (see 6.2). All samples shall be selected at random from each lot. There shall be

no defects.

4.5 Test methods.

2

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business